Nowadays, more and more manufacturers are using thermoforming flexible packaging machines to package and label products. This economical and sustainable packaging solution has greater flexibility. For customer needs, we have two solutions: add labeling equipment on the thermoforming packaging machine, or add a labeling system on the back end of the packaging.

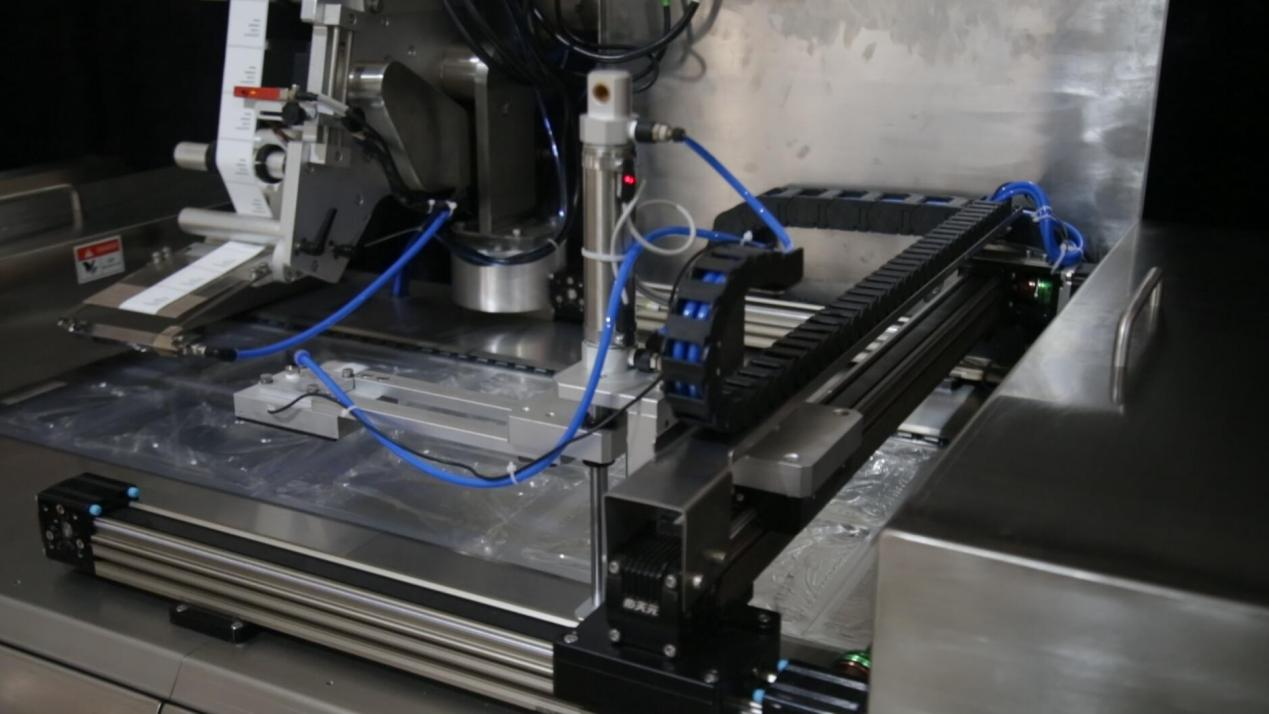

In the first half of this year, our customer ordered a DZL-420R flexible thermoforming vacuum packaging machine from our company, and installed a printing and labeling system between the sealing and cutting area to display their product information.

Features of Thermoforming Flexible Packaging Machine

Efficient packaging

Compared with some semi-automatic vacuum packaging machines, it is more efficient. Automatically complete packaging bag forming, filling (manual or automatic), sealing, cutting and output.

Convenient replacing mold

The machine can be equipped with multiple sets of molds for packaging various sizes of products, and easy to change.

Safety use and device

The machine is designed with protective covers and installed with many sensors to ensure maximum safety.

Advantages of forming

The max forming depth of our thermoforming vacuum packaging machine is 160mm, with a good stretching effect.

Post time: Nov-17-2022