thermoforming vacuum packaging machine for meat : a guide on how to use it effectively

Meat packaging plays a vital role in maintaining its freshness and extending its shelf life. The development of advanced packaging technologies has revolutionized the way we store and transport meat products. One such breakthrough was the thermoforming vacuum packaging machine, which has gained popularity in the food industry due to its efficiency and effectiveness. In this article, we explore the importance of vacuum packaging meat and give you a step-by-step guide on how to use a meat thermoforming vac uum packaging machine.

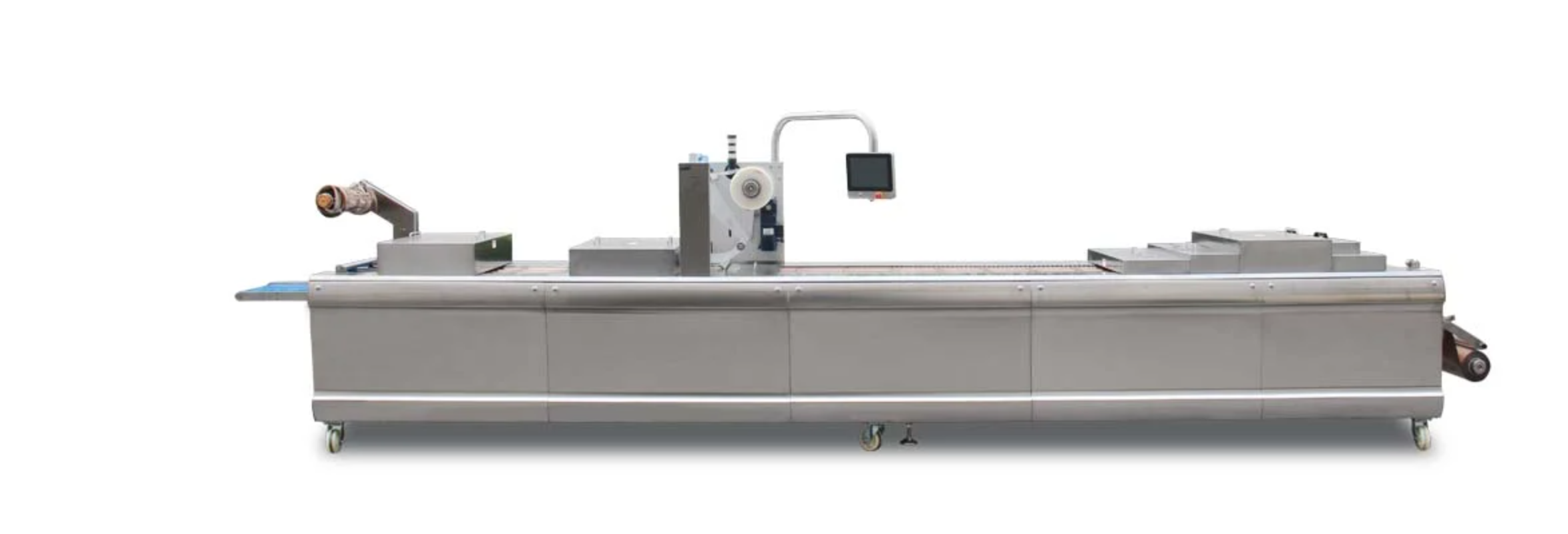

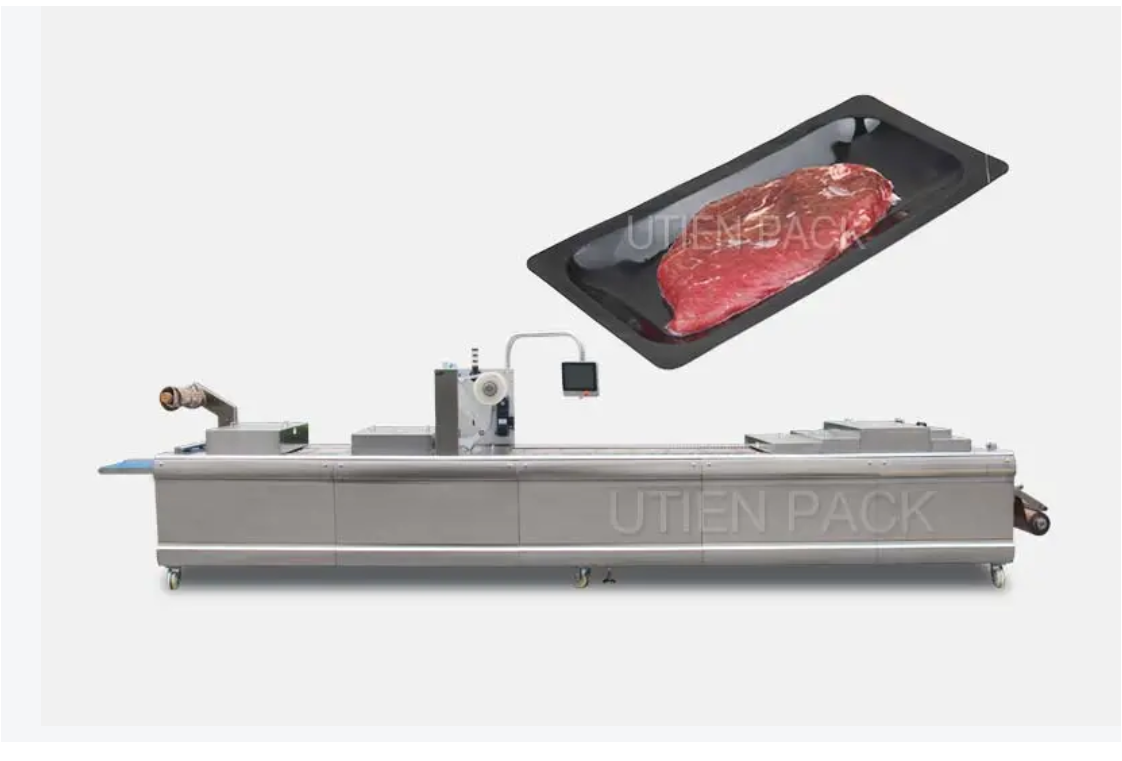

Vacuum packaging is a technology that removes air from packaging materials to create a vacuum environment. It significantly slows down the growth of bacteria, prevents spoilage and preserves the quality and flavor of the meat. Thermoforming vacuum packaging machines are specially designed for meat products. It uses heat to form food-grade plastic sheets into the desired shape, which is then quickly sealed to create an airtight package.

So, how can we effectively use the meat thermoforming vacuum packaging machine? Let’s take a deeper look at the process:

Step 1: Prepare

Make sure the machine is clean and in working order before starting the packaging process. Thoroughly clean and sanitize all surfaces that come into contact with meat to avoid contamination. Also, double check that the plastic sheet is the correct size and has been adequately cut.

Step Two: Load the Machine

Place the pre-cut plastic sheet on the machine platform, making sure it covers the entire area. Press it down lightly to remove any air bubbles or wrinkles that may hinder the sealing process.

Step 3: Arranging the Meat

Place the meat pieces on the plastic sheeting, leaving enough space between each piece to make sure they don’t touch each other. Proper spacing allows for better heat distribution during the vacuum sealing process, ensuring mass preservation and preventing bacterial growth.

Step 4: Seal

Close the lid of the thermoforming vacuum packaging machine and activate the vacuum sealing function. The machine will remove air from the packaging material, effectively sealing the package. After the sealing process is complete, the machine will automatically cut away the excess plastic, providing a clean and professional finish.

Step 5: Clean Up

After packing the desired amount of meat, clean the machine thoroughly to prevent the buildup of meat particles or residue. Wipe down all surfaces with a food-safe disinfectant to make sure there are no residues.

With these simple steps, you can effectively utilize your meat thermoforming vacuum packaging machine to ensure the freshness and quality of your meat products. Remember, proper packaging is critical to maintaining food safety standards and reducing food waste.

In conclusion, meat thermoforming vacuum packaging machines are game changers in the food industry. Its innovative technology enables efficient packaging to extend the shelf life of meat products while maintaining their freshness and taste. By understanding and implementing the above step-by-step guidelines, you can get the most out of this advanced machine and contribute to providing consumers with quality, safe and tasty meat.

Post time: Jun-21-2023